At Bakon Engineering, we offer a comprehensive range of blanket solutions and auxiliary materials designed to meet the exacting standards of the printing industry. From premium Vulcan and Rollin® blankets to Kruse spot varnish blankets, precision cutting strips, and anti-slip underlays, every product in our portfolio supports maximum efficiency and print quality. We also stock adhesive polyester films, fountain solution foils, and various support tapes to ensure seamless operation during mounting and production. All materials are available in industry-standard sizes or customized dimensions to suit your machines. Our catalog includes premium blankets and consumables designed to meet international printing standards.

01

Vulcan and Rollin Blankets

For maximum sharpness and long-lasting use in offset printing, blankets are offered in roll or cut sheet form. Bakon has the largest Vulcan stock in Turkey.

Vulcan®, Rollin®, and Printec® offset printing blankets are produced for sectors such as can printing, heatset printing, newspaper printing, continuous form printing, and sheetfed printing.

■ Do you use UV inks?

■ Do you have a new coating method?

■ Do you have a high-speed / perfecting press?

Vulcan®, Rollin®, and Printec® will help you achieve the best results.

Whatever your expectations from a blanket, Vulcan®, Rollin®, and Printec® have a solution.

Produced by the world’s largest blanket manufacturer, Vulcan® and Rollin® have over 100 years of experience in this field. When this experience is combined with innovative technology, patented production techniques, and a quality-driven approach, these brands stand out from competitors and quickly respond to the ever-changing demands of the global market.

Vulcan®, Rollin®, and Printec®

Vulcan®, Rollin®, and Printec® printing blankets are manufactured to deliver the best possible results. They are produced to the highest quality standards to adapt perfectly to your business needs.

Heatset Printing Blankets

| Product | Color | Layers & Thickness |

|---|---|---|

| Vulcan® Metal | 2-Ply Thickness; machine-specific | |

| Vulcan® Alto ND2 | 3 Ply 1.71 mm | |

| Vulcan® Alto ND2 | 4 Ply 1.96 mm | |

| Vulcan® Alto Plus | 3 Ply 1.71 mm | |

| Vulcan® Alto Plus | 4 Ply 1.96 mm | |

| Vulcan® Mytho Evo | 3 Ply 1.71 mm | |

| Vulcan® 714 Master | 3 Ply 1.71 mm | |

| Vulcan® 714 Master | 4 Ply 1.96 mm |

Newspaper Printing Blankets

| Product | Color | Layers & Thickness |

|---|---|---|

| Vulcan® Metal | 2-Ply Thickness; machine-specific | |

| Vulcan® Royal Web K2 | 4 Ply 1.96 mm | |

| Vulcan® Editor10 Neutral Feed | 3 Ply 1.96 mm | |

| Vulcan® Editor20 Positive Feed | 3 Ply 1.96 mm | |

| Vulcan® 202 | 4 Ply 1.96 mm | |

| Vulcan® 714 Master | 3 Ply 1.71 mm | |

| Vulcan® 714 Master | 4 Ply 1.96 mm | |

| Rollin® Avenir | 3 Ply 1.71 mm | |

| Rollin® Polycell | 4 Ply 1.96 mm |

Metal Sheet Offset Printing Blankets

| Product | Color | Layers & Thickness |

|---|---|---|

| Vulcan® Combo | 4 Ply 1.96 mm | |

| Vulcan® Eco | 4 Ply 1.96 mm | |

| Vulcan® Folio UV | 3/4 Ply 1.96 mm | |

| Vulcan® UV | 3 Ply 1.71 mm | |

| Vulcan® UV | 4 Ply 1.96 mm | |

| Vulcan® 714 Strip | 4 Ply 1.96 mm | |

| Vulcan® 714 Master | 3 Ply 1.71 mm | |

| Vulcan® 714 Master | 4 Ply 1.96 mm | |

| Vulcan® Super UV | 4 Ply 1.96 mm | |

| Vulcan® Kart One UV | 4 Ply 1.96 mm |

Packaging Printing Blankets

| Product | Color | Layers & Thickness |

|---|---|---|

| Vulcan® Kartone UV | 3/4 Ply 1.96 mm | |

| Vulcan® Combo | 4 Ply 1.96 mm | |

| Vulcan® Eco | 4 Ply 1.96 mm | |

| Vulcan® UV | 3 Ply 1.71 mm | |

| Vulcan® UV | 4 Ply 1.96 mm | |

| Vulcan® 714 Strip | 4 Ply 1.96 mm | |

| Vulcan® Image Blue | 4 Ply 1.96 mm | |

| Vulcan® 714 Master | 3 Ply 1.71 mm | |

| Vulcan® 714 Master | 4 Ply 1.96 mm | |

| Rollin® Infinity Plus | 4 Ply 1.96 mm | |

| Rollin® Metro | 4 Ply 1.96 mm |

Continuous Form Printing Blankets

| Product | Color | Layers and Thickness |

|---|---|---|

| Vulcan® Royalform | 2 Ply 0.90 mm | |

| Vulcan® Royalform | 2 Ply 0.95 mm | |

| Vulcan® Royalform | 2 Ply 1.00 mm | |

| Vulcan® Royalform | 2 Ply 1.05 mm | |

| Vulcan® Royalform UV | 2 Ply 0.90 mm | |

| Vulcan® Royalform UV | 2 Ply 0.95 mm | |

| Vulcan® Royalform UV | 2 Ply 1.00 mm | |

| Vulcan® Royalform UV | 2 Ply 1.05 mm | |

| Vulcan® 714 Master | 3 Ply 1.71 mm | |

| Vulcan® 714 Master | 4 Ply 1.96 mm |

02

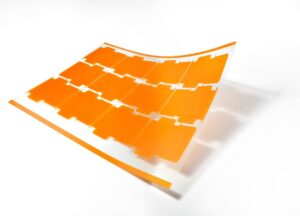

Kruse Lacquer Blankets

With Italian Kruse quality, spot coating applications offer high precision and easy installation.

Perfect transfer performance in all coating applications.

With polyester or rubber surface options, they are available in all sizes for your overprint coating needs.

■ Uniform distribution

■ UV/Conventional

■ Long run length

■ Easy stripping

03

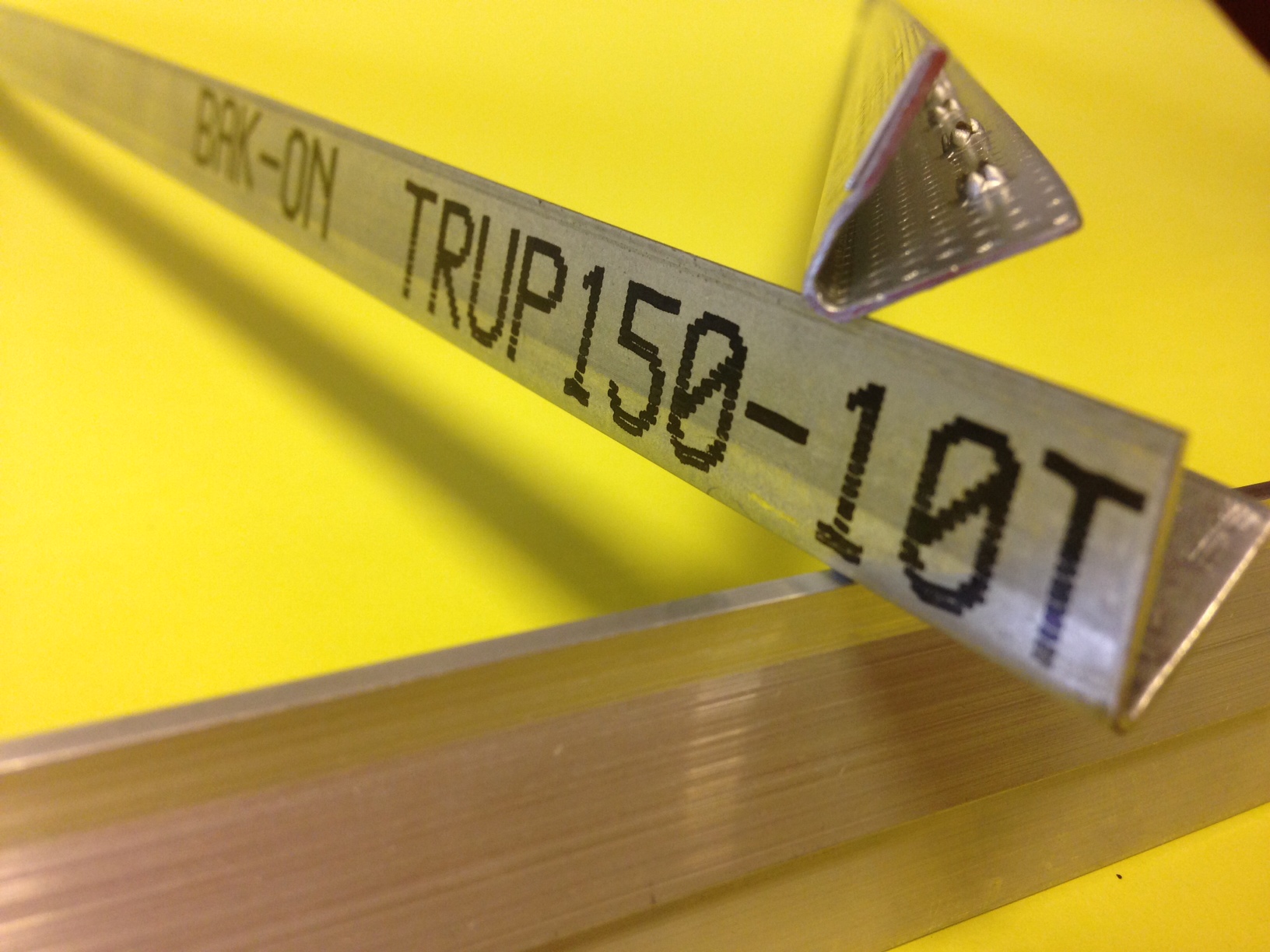

Steel and Aluminum Blanket Bars

The first bar systems produced domestically in Turkey. Cutting and drilling in the required dimensions is supported.

We supply steel and aluminum blanket bars in requested sizes for all types of bar needs.

04

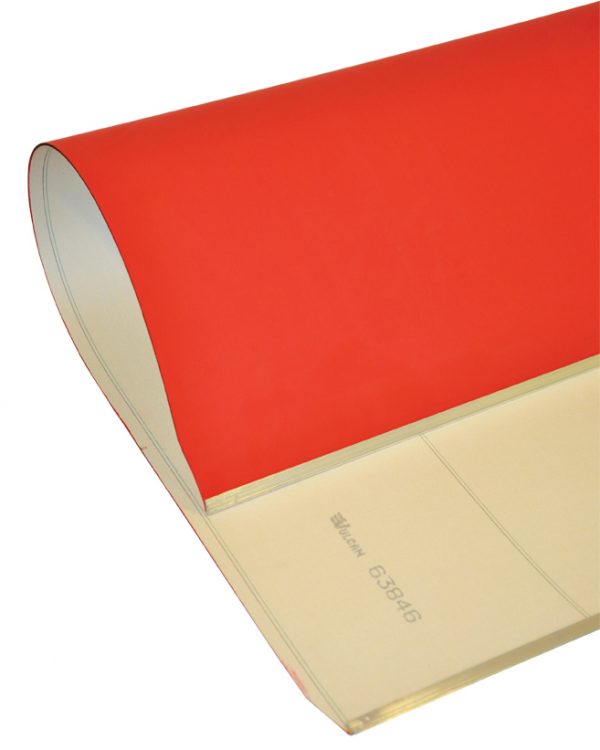

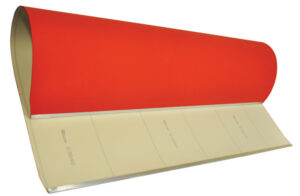

Underpacking Sheets

Underpacking sheets are support layers placed beneath the printing blanket and are available in various hardness levels depending on machine specifications.

Advantages of using underpacking sheets instead of cardboard under the blanket:

Precise Thickness Control:

▪ When cardboard is used as the lower layer instead of underpacking sheets, variations in thickness on the surface are inevitable. Since underpacking sheets are manufactured with more consistent thickness, the desired print quality is ensured immediately — without trial and error, which would otherwise take time.

Cost-Effective and High-Quality Printing:

▪ Underpacking sheets are produced with tightly controlled tolerances and retain their characteristics throughout print runs. This ensures consistent quality in terms of dot gain, ink transfer, and print density. As a result, optimum print pressure is achieved between plates, blankets, and impression cylinders, maximizing print quality while minimizing common problems such as ghosting, slurring, and dot distortion.

Safe Against Slipping and Movement:

▪ A key benefit: Underpacking sheets eliminate the risk of slippage between blanket and cylinder. Even during high-speed or long print runs, sheets stay securely in place — significantly reducing press stoppages and print quality issues.

Quick and Easy Color Identification:

▪ Each thickness of underpacking sheet is color-coded. This makes it easy to identify and select the correct sheet just by color — no need to measure the thickness every time.

Moisture Resistance:

▪ Since underpacking sheets are compressed during the printing process, they are not prone to expansion or swelling. Unlike cardboard, they do not absorb moisture after print stops and are far less likely to deform when reused.

| Standard Underpacking Sheet Sizes | Underpacking Sheet Thicknesses and Colors |

|---|---|

| 605 × 740 mm | 0.10 mm – Cream |

| 795 × 1030 mm | 0.15 mm – Brown |

| 1150 × 1450 mm | 0.20 mm – Green |

| Custom sizes available upon request. | 0.25 mm – Orange |

| 0.30 mm – Yellow | |

| 0.40 mm – Blue | |

| 0.50 mm – Grey |

05

Folex Adhesive Films

Adhesive films save time during mounting and ensure smooth, secure adhesion.

ADHESIVE ASTROLON

Machines from leading manufacturers like Heidelberg, MAN, KBA, Ryobi, Komori, WIFAG, Goss, and Solna often come factory-equipped with adhesive astrolon films at the blanket or underblanket level.

In such cases, Folex adhesive astrolon is preferred as a direct replacement.

Folex adhesive astrolon is a polyester-based film that resists stretching, shrinkage, and swelling caused by moisture or heat.

Thanks to its special adhesive structure, Folex astrolon provides long-lasting and secure mounting. Its micro-void adhesive surface ensures easy and bubble-free application without trapping air between layers.

Since adhesion depends entirely on the press cylinder’s pressure, the bond becomes permanent during printing. No additional adhesive is needed.

Important:

Before applying, all cylinder surfaces must be thoroughly cleaned. During application, ensure the adhesive film is fully secured and that no air bubbles remain underneath.

Advantages:

▪ No stretching or shrinking

▪ Does not swell due to fountain solution

▪ Prevents fountain solution from entering the cylinder and causing corrosion

▪ Maintains long-term adhesion strength without shifting

▪ Can be repositioned during mounting thanks to its micro-void adhesive

▪ Resistant to all types of printing chemicals

▪ No residue left behind when removed

Available Thicknesses:

0.04 mm, 0.08 mm, 0.10 mm, 0.12 mm, 0.14 mm,

0.16 mm, 0.18 mm, 0.20 mm, 0.24 mm, 0.28 mm, 0.30 mm,

0.35 mm, 0.40 mm, 0.45 mm, 0.50 mm

06

Ink Fountain Foil

An ink fountain foil is a long-life consumable designed to keep ink fountains clean and reduce ink consumption.

Specifically made for Heidelberg presses,

it enables rapid ink changes and helps minimize downtime during color changes.

Ink Fountain Foil Sizes:

| Foil Name | Press Model | Dimensions |

|---|---|---|

| INK FOIL SM 52 | SPEEDMASTER | 548 × 200 × 0.19 mm |

| INK FOIL SM 74 | SPEEDMASTER | 775 × 232 × 0.19 mm |

| INK FOIL CD 74 | SPEEDMASTER | 775 × 228 × 0.19 mm |

| NEW | ||

| INK FOIL SM 102 | SPEEDMASTER | 1067 × 232 × 0.19 mm |

| INK FOIL CD 102 | SPEEDMASTER | 1067 × 232 × 0.19 mm |

| INK FOIL XL 162 | SPEEDMASTER | 1673 × 265 × 0.19 mm |

| NEW | ||